High-power Direct Diode Laser DlightT

Reference: FOL-Dlight-Series

- Send to a friend

- Remove this product from my favorite's list.

- Add this product to my list of favorites.

Product description

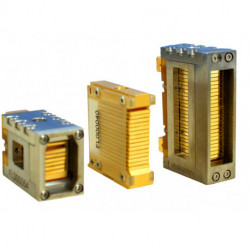

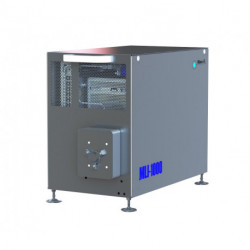

High-power Direct Diode Laser Head Dlight from Focuslight

Integrators welcome: We offer competent support for this OEM-product.

Applications:

Dlight cladding system is widely used in various industrial fields,

such as:

With a short wavelength and 50% high power conversion efficiency, the new product has a significant advantage over the traditional CO2 laser in regards of laser cladding and material surface treatment. From performance point of view, the stability of the diode laser is significantly higher than the CO2 laser. In terms of processing, the diode laser has a smaller heat affected zone, a stronger processing control, and its cladding and hardening quality is much higher than the CO2 laser. As to flexibility, the size of the diode laser is almost 1/30 of the CO2 laser, so the diode laser system can be used as a mobile laser processing station to repair and process the work piece that is inconvenient to move.

Integrators welcome: We offer competent support for this OEM-product.

Applications:

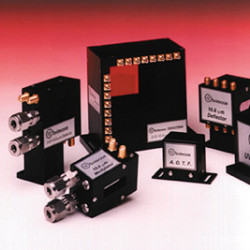

- Direct laser material processing

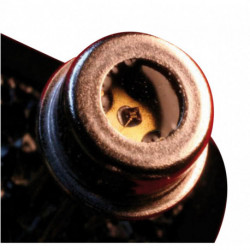

- Laser Cladding in manufacturing and repair service

- Surface treatment, e.g. for anticorrosion, alloying, enforcement

Technical data:

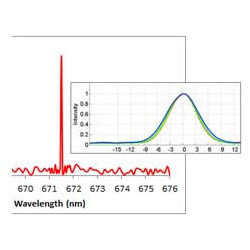

Wavelengths: 808nm, 976nm

Power: 2kW, 3kW, 4kW, 5kW

Spot size [mm x mm] at 2kW: 4 x 4 or 2 x 4

Spot size [mm x mm] at > 2kW: 2.5 x 11.5

Working distance: 300mm

Advantages of the Dlight Diode Laser Based Cladding System

- High conversion efficiency

- Stability of Output Power

- Large spot size

- Small heat affected zone

- Compact size

- Low running cost

- Uniform energy density distribution

- Short wavelength favors for high metal absorption

- Long working distance

- High compatibility to users' applications

- Easy maintenance

Dlight cladding system is widely used in various industrial fields,

such as:

- Metallurgical industry,

- Petroleum & chemical industry,

- Electric power industry,

- Mine industry,

- Aerospace industry.

With a short wavelength and 50% high power conversion efficiency, the new product has a significant advantage over the traditional CO2 laser in regards of laser cladding and material surface treatment. From performance point of view, the stability of the diode laser is significantly higher than the CO2 laser. In terms of processing, the diode laser has a smaller heat affected zone, a stronger processing control, and its cladding and hardening quality is much higher than the CO2 laser. As to flexibility, the size of the diode laser is almost 1/30 of the CO2 laser, so the diode laser system can be used as a mobile laser processing station to repair and process the work piece that is inconvenient to move.

High-power Direct Diode Laser DlightT

High-power Direct Diode Laser DlightT