View larger

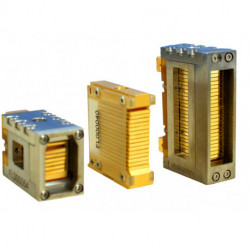

View larger Blue high-performance laser for laser processing

Reference: NUB-AO150

SPATTER-FREE WELDING OF COPPER AND YELLOW METALS WITH HIGH POWER BLUE LASERS

- Send to a friend

- Remove this product from my favorite's list.

- Add this product to my list of favorites.

Product description

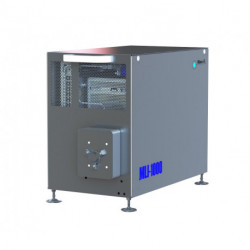

1. High Power Blue Lasers AO-150

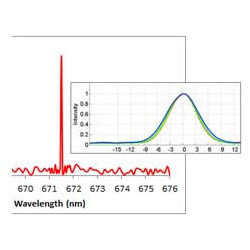

The 450 nm laser AO-150 is an air-cooled diode laser with 150 W output power in an SMA fiber connector with a 200 ?m core diameter. This power is available for cw operation or modulated with up to 50 kHz.

2. Characteristics of blue AO-150 lasers

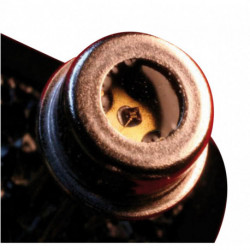

This new generation of blue diode lasers has been developed for the micro- and macromaterial processing of copper, its alloys and precious metals. There are a number of highly reflective metals with limited absorption in the IR range, or even in the green range, where the blue laser radiation has significant advantages, especially in welding.

In the microscopic as well as the macroscopic observation of the welding process, the homogeneous course of the liquid phase of the welding is more reminiscent of a soft flow of wax than the known welding of metals.

A spatter-free machining process is characteristic for all types of welding. This applies in the case of actual welding, as well as in the case of application welding and drilling, even at a power output of 150 W.

Specifications | ||

AO 150 | Units | Typical |

Optical |

|

|

Wavelength | nm | 450 |

Bandwidth | nm | 10 |

Output Power | W | 150 |

Power Adjustment | % | 0 - 100 |

Power Stability (8 hours) | % | < 3 |

Fiber Diameter (Core) | µm | 200 |

Fiber Numerical Aperture | NA | 0.22 |

Beam Product Parameter | mm - mrad | < 22 |

Standard Fiber Length | m | 5 |

Connector Type |

| QBH |

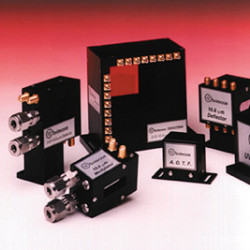

3. Advantages of blue lasers (compared to IR lasers)

The application-oriented platform of blue high-performance lasers will decisively convert metal cutting and welding as well as additive production.

- Significantly better absorption -> the energy transfer of blue lasers is 2- to 20-times higher for most materials

- Blue lasers provide 5- to 20-times faster material processing speeds -> higher throughput

- Blue lasers have a 5 times smaller focus point -> allows greater precision, higher resolution and better production quality (for example in 3D printing)

- Unique, spatter-free performance in material welding -> also guarantees better manufacturing quality

4. Applications of blue AO-150 lasers

The advantages of the blue wavelength are in particular the spatter-free welding of copper, its alloys and other precious metals.

- Micromachining

- Welding of batteries

- Welding of electronic components

- Surfacing and surface structuring

Blue high-performance laser for laser processing

Blue high-performance laser for laser processing